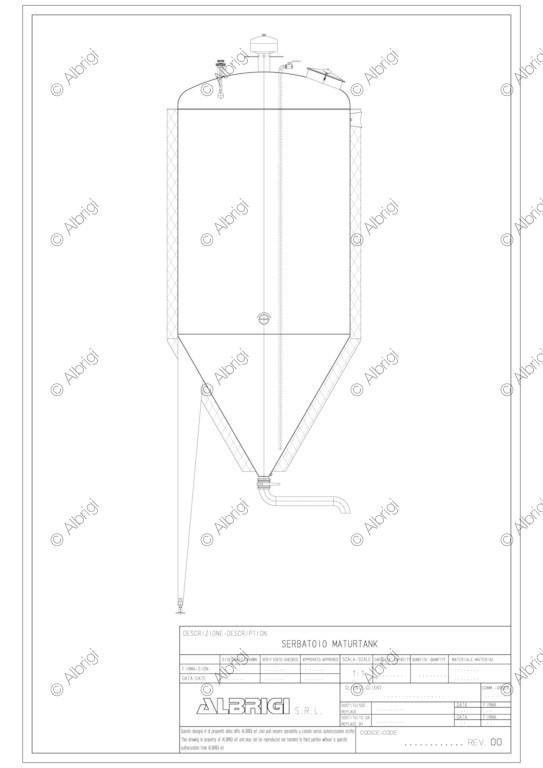

MATURTANK

USE

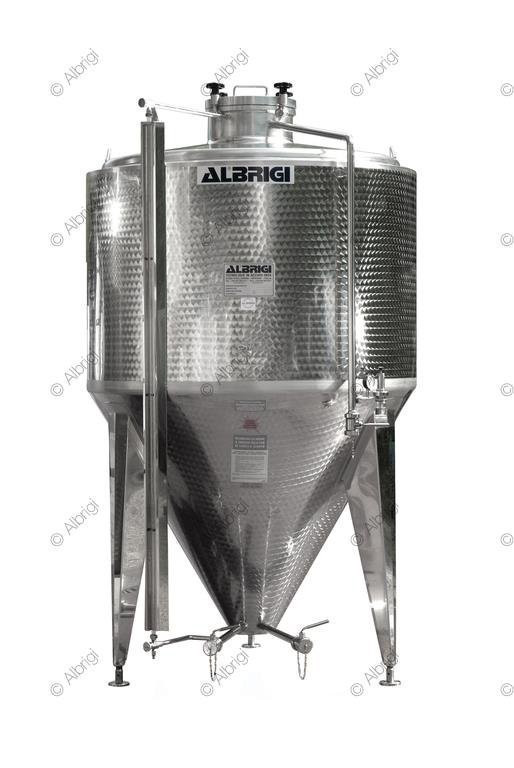

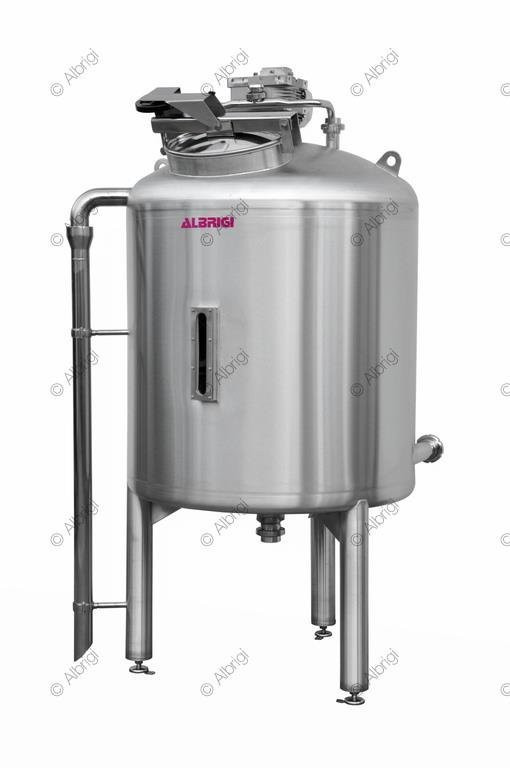

The Maturtank is a tank designed to precisely manage the maturation phases of products that require controlled temperature and pressure conditions. Ideal for processes where time, rest, and stability are essential to enhance the organoleptic qualities of the final product.

FEATURES

- Temperature and Pressure Control: Designed to maintain set temperatures and pressures during maturation processes.

- Robust Construction: Made of stainless steel for durability and strength.

- Thermoconditioning: Equipped with a conditioning system to develop the temperatures required for product maturation.

- Versatility: Suitable for various types of liquid products requiring specific ripening conditions.

ADVANTAGES

- Product Quality: Maintains optimum ripening conditions, improving final product quality.

- Operational Efficiency: Facilitates maturation processes, optimising operating times and conditions.

- Safety and Reliability: Built with high quality materials, it guarantees safety and reliability over time.

- Flexibility: Suitable for various industrial applications, it offers a versatile solution for ripening processes.

The Maturtank is ideal for companies that need a reliable tank for the maturation of liquid products. Its ability to maintain controlled temperature and pressure conditions makes it essential for improving both the efficiency and quality of the production process.

Availability:

Only by Order

Valves:

Ø and model on request

Type:

Closed

- fermentation

- processing

- heating

IT

IT

CN

CN

FR

FR

DE

DE

PT

PT

RU

RU

ES

ES

AR

AR

NI

NI